Rev up the volume and grab your wrenches, fellow truck enthusiasts! Today, I’m going to show you how to wire your air horns without a relay. It’s a nifty little trick that can save you some time and money, and I’m here to guide you through the process step by step. So, let’s get our hands dirty and make some noise!

Why Wire Air Horns Without a Relay?

Before we dive into the nitty-gritty of wiring air horns without a relay, you might be wondering why you’d want to do that in the first place. Well, let me break it down for you:

- Simplicity: Using a relay adds an extra component to the wiring setup. By eliminating the relay, we can simplify the installation process and save some bucks along the way.

- Availability: Sometimes finding the right relay for your air horns can be a hassle. By bypassing the relay, you can get your horns up and running using readily available wiring materials.

- Emergency situations: In case of an emergency, you might not have the luxury of time to hunt down a relay. Knowing how to wire your air horns without one can be a lifesaver.

Now that we’ve got our reasons sorted, let’s jump into the practical side of things.

What You’ll Need

To wire your air horns without a relay, you’ll need a few tools and materials:

- Air horns (with compressor and air tubing)

- Wire cutters/strippers

- Electrical tape

- Ring terminals

- Crimping tool

- Inline fuse holder

- Fuse (according to your air horn’s power requirements)

- Wrenches or socket set

Step-by-Step Wiring Guide

Follow these 8 steps to wire your air horns without a relay:

1. Disconnect the Battery

Before starting any electrical work, it’s essential to disconnect the negative terminal of your truck’s battery. This step ensures your safety and prevents any accidental electrical mishaps.

2. Locate a Power Source

Look for a suitable power source near the air horns. Ideally, you want to find a fused connection that only receives power when the ignition is turned on. This could be a cigarette lighter socket or an accessory fuse box. Make sure you choose a power source that can handle the electrical load of your air horns.

3. Prepare the Wiring

Measure and cut two lengths of wire that will reach from the power source to the air horns. It’s a good idea to leave some extra length for flexibility. Use wire cutters/strippers to strip about half an inch of insulation from the ends of the wires to expose the metal.

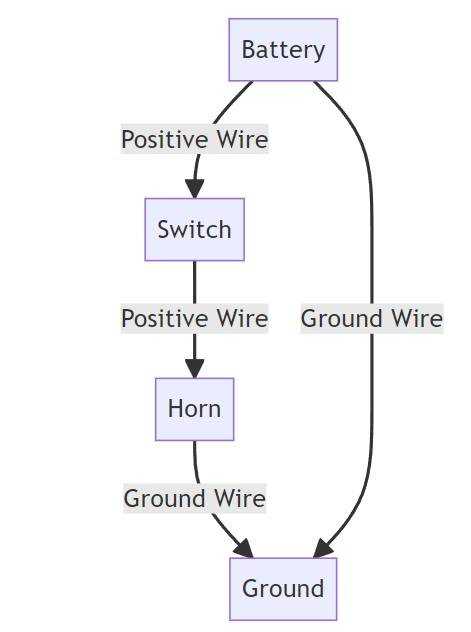

4. Connect the Power Wire

Take one end of the power wire and connect it to the power source you identified in the previous step. To make a secure connection, use a ring terminal and a crimping tool. Slide the ring terminal over the exposed metal of the wire, then crimp it tightly to ensure a solid connection.

5. Connect the Ground Wire

Find a suitable grounding point near the air horns. This could be a bolt or screw attached to the truck’s chassis. Ensure that the grounding point is clean and free of any paint or rust. Attach the other end of the wire to the grounding point using a ring terminal and a crimping tool. This establishes a solid ground connection for your air horns.

6. Fuse it Up

Install an inline fuse holder on the power wire, close to the power source. The fuse holder acts as a protective measure in case of electrical faults or overloads. Open the fuse holder and insert the appropriate fuse based on your air horn’s power requirements. The fuse rating should match or slightly exceed the current draw of your air horns. This helps prevent damage to the wiring or the air horn components.

7. Connect the Air Horns

Now it’s time to connect the air horns themselves. Attach the air tubing from the compressor to the air horns, ensuring that the connections are secure and airtight. Follow the manufacturer’s instructions for proper installation and sealing techniques.

8. Test the Setup

With all the connections in place, it’s time to test your newly wired air horns. Reconnect the battery by attaching the negative terminal. Turn on your truck’s ignition and press the horn button. If everything is wired correctly, you should hear the powerful blast of your air horns resonating through the air.

Final Thoughts

Wiring air horns without a relay is a feasible DIY project for truck owners and drivers. By following this guide, you can save time and money while still enjoying the ear-catching power of air horns. Just remember to prioritize safety and double-check all connections before revving up the decibels.

Now go out there, honk with confidence, and let your truck’s voice be heard!

Stay tuned for more truck-related tips and tricks on my blog. Until next time, happy trucking!